The Convergence of Advanced Packaging and Thermal Management

In the relentless pursuit of the power density revolution in miniaturized energy storage, the synergy between advanced packaging and thermal management has emerged as a critical frontier. As energy storage devices become more compact and powerful, the integration of these two aspects is no longer a luxury but a necessity to unlock their full potential.

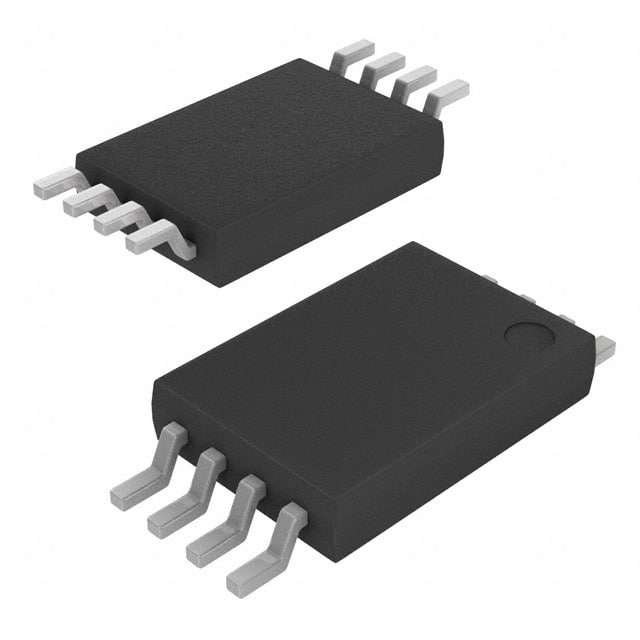

Advanced packaging techniques are redefining the boundaries of energy storage design. System - in - Package (SiP) technology, which integrates multiple components, including electrodes, electrolytes, and control circuits, into a single, compact unit, is gaining traction. This approach minimizes the distances between components, reducing electrical resistance and enabling faster charge transfer. For example, by stacking thin - film batteries with integrated power management circuits, SiP solutions can achieve a significant boost in power density, optimizing space utilization while enhancing overall system performance. Additionally, flexible packaging materials are revolutionizing the form factor of energy storage devices. These materials allow for the creation of bendable, wearable, and conformable batteries, expanding their application scope from traditional electronics to emerging fields like smart textiles and medical implants.

However, the increased power density brought about by advanced packaging exacerbates thermal management challenges. With more energy being packed into a smaller space, the heat generated during operation can quickly reach critical levels. This is where innovative thermal management solutions come into play. Nanofluids, a type of coolant composed of nanoparticles suspended in a base fluid, are showing great promise. The presence of nanoparticles significantly enhances the thermal conductivity of the base fluid, enabling more efficient heat transfer. Research has demonstrated that nanofluids can reduce the operating temperature of energy storage devices by up to 20%, effectively preventing thermal runaway and extending the lifespan of the batteries.

Another cutting - edge thermal management strategy involves the use of metamaterials. These artificially engineered materials possess unique thermal properties that can manipulate heat flow in unconventional ways. Metamaterials can be designed to direct heat away from critical components, creating thermal barriers or enhancing heat dissipation in specific directions. In the context of energy storage, this technology allows for more precise control over temperature distribution, ensuring that each part of the device operates within its optimal thermal range.

The integration of advanced packaging and thermal management also has implications for the recyclability of energy storage devices. By carefully selecting materials and design strategies, manufacturers can make it easier to disassemble and recycle components at the end of the device's life cycle. For instance, using dissolvable adhesives in packaging can simplify the separation process, while modular thermal management systems can be easily removed and recycled independently.

Looking ahead, the future of the power density revolution lies in the seamless integration of these technologies. Collaborative efforts between materials scientists, engineers, and industry players will be crucial in developing holistic solutions that balance power density, thermal performance, and sustainability. As these advancements continue to unfold, miniaturized energy storage devices will not only become more powerful and efficient but also more environmentally friendly, driving innovation across a wide range of industries and contributing to a more sustainable energy future.

-

AT21CS01-STUM10-T Microchip Technology

-

AT24CSW010-UUM0B-T Microchip Technology

-

MX25R1635FM1IL0 Macronix

-

AT24C128C-XHM-T Microchip Technology

-

M24128X-FCU6T/TF STMicroelectronics

-

ATSHA204A-STUCZ-T Microchip Technology