Shaping the Future of Miniaturized Electronics

In the ever - evolving landscape of electronics, the pursuit of higher power density has emerged as a critical frontier, with advanced packaging and thermal management technologies at the forefront of this revolution. These two seemingly distinct fields are now converging in ways that not only enhance the performance of electronic devices but also redefine their design possibilities and sustainability prospects.

Advanced packaging techniques have become a game - changer, enabling the miniaturization of complex electronic systems. Fan - Out Wafer - Level Packaging (FOWLP) is one such technology that has gained significant momentum. Unlike traditional packaging methods, FOWLP allows for the redistribution of electrical connections on the wafer level, eliminating the need for bulky printed circuit boards. This results in a more compact form factor and reduced signal delay, facilitating the integration of more components into a smaller space. For example, in the development of high - performance mobile processors, FOWLP enables the incorporation of multiple cores, memory modules, and I/O interfaces in a single package, significantly boosting power density.

However, as power density increases, so does the heat generated by these densely packed components. Thermal management has thus become a make - or - break factor in the performance and reliability of electronic devices. Phase - change materials (PCMs) are emerging as a key solution in this regard. PCMs can absorb and store large amounts of heat during the phase transition from solid to liquid, effectively regulating temperature fluctuations. In electronics, PCMs are often integrated into the packaging layers, where they act as a thermal buffer, preventing overheating and ensuring stable operation. A recent study showed that the use of PCMs in laptop batteries can reduce peak operating temperatures by up to 15°C, extending battery life and improving overall system performance.

The integration of artificial intelligence (AI) into thermal management systems is another groundbreaking development. AI - enabled sensors and algorithms can continuously monitor the temperature and power consumption of electronic components in real - time. Based on this data, the system can dynamically adjust the cooling strategy, optimizing energy efficiency while maintaining optimal operating temperatures. For instance, in data centers, AI - driven thermal management systems can predict hotspots before they occur and direct cooling resources precisely where they are needed, reducing energy waste by up to 30%.

From an environmental perspective, the convergence of advanced packaging and thermal management is also driving sustainable innovation. The use of biodegradable materials in packaging, such as plant - based polymers, not only reduces the environmental impact of electronic waste but also offers comparable thermal and mechanical properties to traditional plastics. Additionally, more efficient thermal management means lower energy consumption, contributing to a reduced carbon footprint.

As the demand for smaller, faster, and more energy - efficient electronic devices continues to grow, the synergy between advanced packaging and thermal management will play an increasingly vital role. The future holds the promise of even more innovative solutions, such as 3D - printed thermal structures integrated directly into the packaging and self - healing materials that can repair thermal interfaces over time. These advancements will not only fuel the next generation of consumer electronics but also have far - reaching implications for industries such as automotive, aerospace, and healthcare, where reliable and high - performing electronics are essential.

-

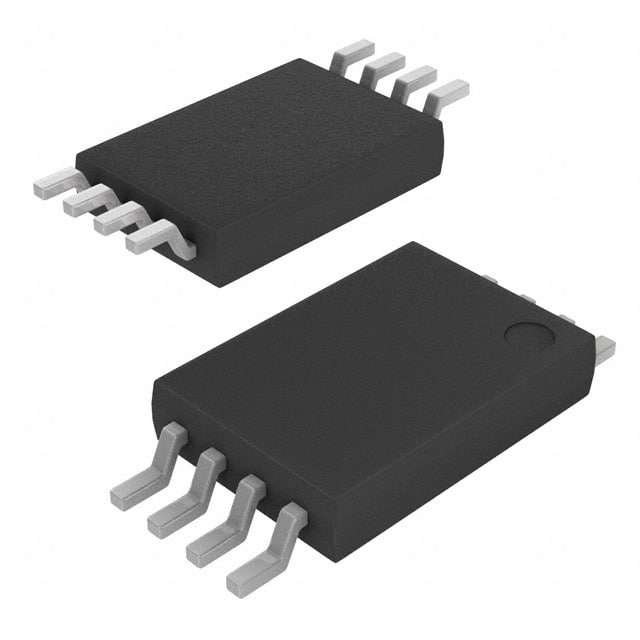

AT21CS01-STUM10-T Microchip Technology

-

AT24CSW010-UUM0B-T Microchip Technology

-

MX25R1635FM1IL0 Macronix

-

AT24C128C-XHM-T Microchip Technology

-

M24128X-FCU6T/TF STMicroelectronics

-

ATSHA204A-STUCZ-T Microchip Technology