How Advanced Packaging and Thermal Management Redefine Electronics Boundaries

In the ever - evolving landscape of electronics, the symbiotic relationship between advanced packaging and thermal management is no longer a mere supporting act-it's the driving force behind a new era of technological innovation. This synergy is not just about shrinking device sizes; it's a complex interplay that unlocks unprecedented performance, reliability, and sustainability across diverse industries.

Advanced packaging technologies have undergone a transformative evolution. Chip - on - Wafer - on - Substrate (CoWoS) stands out as a prime example. By stacking multiple chips in a vertical arrangement and connecting them through interposers, CoWoS enables a significant leap in integration density. In high - end graphics processing units (GPUs) for data centers, CoWoS allows for the integration of multiple compute dies, high - bandwidth memory (HBM), and I/O chips. This not only reduces the physical footprint but also minimizes signal latency, enhancing overall computational efficiency. For instance, the latest AI - optimized GPUs leveraging CoWoS can achieve up to 30% higher data transfer rates compared to traditional packaging methods, a critical factor in handling the massive data volumes generated by machine learning algorithms.

Yet, this increase in integration density comes with a heat - related challenge. The heat flux generated by densely packed high - performance components can reach levels that threaten device functionality. To combat this, micro - fluidic cooling has emerged as a revolutionary thermal management solution. Micro - channels, etched directly into the package substrate, allow for the circulation of coolant at a microscale. In a recent experiment conducted by a leading research institute, a micro - fluidic - cooled CPU demonstrated a 25% reduction in thermal resistance compared to traditional air - cooled counterparts. The coolant's ability to carry away heat more efficiently than air ensures that components can operate at higher clock speeds without overheating, effectively boosting performance.

The marriage of these technologies is particularly evident in the automotive sector. Electric vehicles (EVs) rely on battery management systems (BMS) that require both compact packaging and effective thermal control. Fan - Out Wafer - Level Packaging (FOWLP) is used to miniaturize the BMS circuitry, while phase - change materials (PCMs) are integrated to manage the heat generated during battery charging and discharging. A real - world application in a popular EV model showed that this combination improved the BMS's thermal stability, extending the battery's lifespan by up to 20%.

Sustainability is another frontier where this synergy is making waves. 3D - printing technology, when applied to packaging, allows for the creation of customized thermal structures using recycled materials. These structures can be optimized for specific heat dissipation requirements, reducing the need for excess material and energy - intensive manufacturing processes. Additionally, the use of advanced thermal interface materials (TIMs) made from renewable resources not only enhances heat transfer but also minimizes the environmental impact associated with electronic waste.

Looking ahead, the future of this convergence holds even more promise. The development of self - regulating thermal management systems, which use smart materials that change their thermal conductivity in response to temperature variations, could revolutionize device design. Moreover, the integration of neural network - based algorithms into thermal management systems will enable more accurate predictions of thermal behavior, further optimizing energy usage. As these advancements continue to unfold, advanced packaging and thermal management will remain at the forefront, shaping the next generation of electronics and driving innovation across multiple sectors.

-

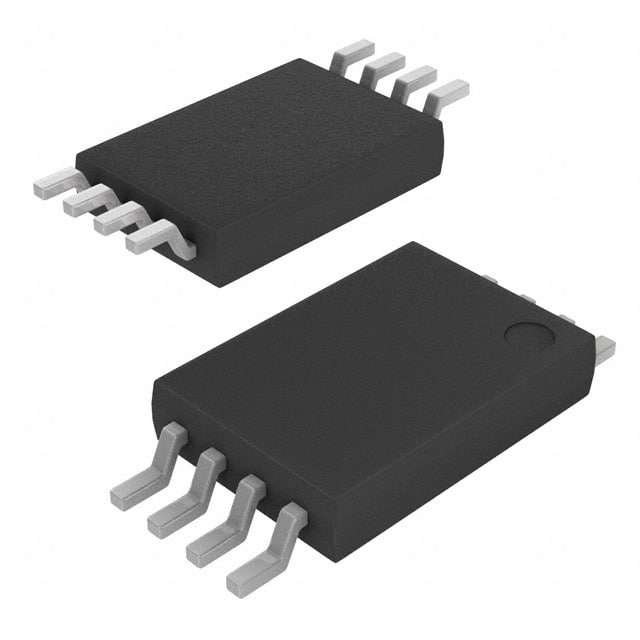

AT21CS01-STUM10-T Microchip Technology

-

AT24CSW010-UUM0B-T Microchip Technology

-

MX25R1635FM1IL0 Macronix

-

AT24C128C-XHM-T Microchip Technology

-

M24128X-FCU6T/TF STMicroelectronics

-

ATSHA204A-STUCZ-T Microchip Technology